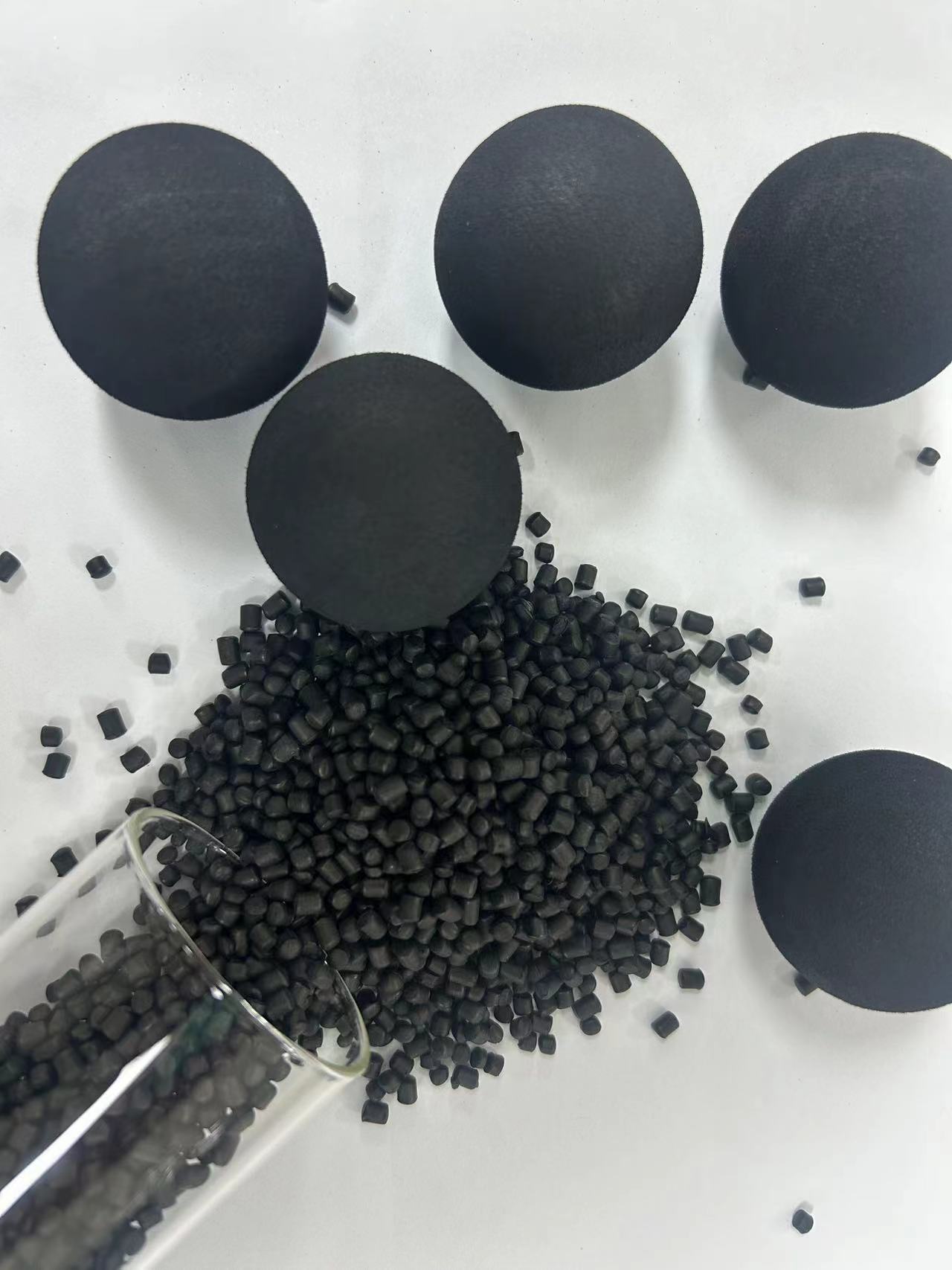

EVA soft material modified rubber particles TPES

Category:

PRODUCTS

TPES

This product can increase elasticity and softness in the processing and production of EVA, PE, SBS, PS, PP and other products. This product has good compatibility with EVA material, especially in EVA injection slippers or flat foam, it can reduce the hardness of the material, make it more soft and elastic, and improve the grade of the product.

Product Description

Product description

This product can increase elasticity and softness in the processing and production of EVA, PE, SBS, PS, PP and other products. This product has good compatibility with EVA material, especially in EVA injection slippers or flat foam, it can reduce the hardness of the material, make it more soft and elastic, and improve the grade of the product.

Product properties

| Model | Densityg/m³ |

Shore hardness Shore A |

Melt index g/10min (180℃ 5.00kg) |

Tensile Strength Mpa |

Elongation at break%% |

Tear strength KN/m |

| ISO 1183 | ISo 868 | ISO 1133 | ISO 527 | ISO 527 | ISO 34 | |

| 2500 | 1.05 | 15 | 5 | 4.2 | 650 | 55.2 |

| 2510 | 0.94 | 6 | 10 | 8.5 | 800 | 50.5 |

| 2512 | 1.06 | 10 | 6 | 5.2 | 720 | 52.5 |

| 2513 | 1.1 | 10 | 5.5 | 4.8 | 850 | 52.1 |

| 2515 | 1.09 | 32 | 5 | 9 | 900 | 62.5 |

| 2516 | 1.07 | 18 | 8.5 | 8.8 | 750 | 54.5 |

| 2518 | 1.17 | 20 | 6.5 | 6.2 | 700 | 55.6 |

| 2518A | 1.22 | 15 | 8 | 7.5 | 680 | 54.6 |

| 2518B | 1.19 | 15 | 7.5 | 7.2 | 620 | 55.9 |

| 2520 | 1.19 | 12 | 5 | 6.2 | 580 | 53 |

| 2520A | 1.3 | 12 | 5.5 | 7 | 660 | 53.2 |

| 2530 | 1.3 | 12 | 3.5 | 8 | 550 | 51.5 |

| 3210 | 1.28 | 28 | 4 | 8.5 | 650 | 58.9 |

| 3310 | 1.18 | 28 | 4.5 | 9 | 700 | 58 |

Note: The above data is the average value of the test, for reference only

Features

● Shore hardness: 6~30A

● Softening temperature: 60℃

● Melt index (180℃/5kg): 4~10g/10min

● Excellent tensile strength and tensile elongation, excellent elasticity and good plasticity

● No toxic ingredients, green and environmentally friendly

Instructions

It can be used in combination with the above polymer materials without changing the original production process and process, and the effect is particularly ideal when the addition amount is 5% to 20%.

MESSAGE